|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

textile operations of JCT Limited are spread over two sites. The larger

composite mill is at Phagwara in Punjab, which is in the northern part

of India and the second composite mill at Sriganganagar in Rajasthan in

the northwestern part of India.

Modernization of the plants has resulted

in state-of-the-art manufacturing facilities in Spinning, Weaving and

Processing. The mills manufacture a wide range of 100 per cent Cotton

and Blended, Woven Grey and Processed fabric in varieties of weaves and

finishes in weights ranging from 110 gsm to 480 gsm in single as well

as plied yarns. The mills manufacture up to 44 million metres of fabric

per annum.

The

entire requirement of yarn is produced in-house with a count range of

NE 6s OE to 20s OE, Ring Spun yarn NE 10s to 40s in Single ply and Ring Spun yarn NE 10s to 100s in 2 ply.

The fabric is woven on Sulzer Shuttleless looms in

a wide range of weaves and weights.

The processing takes place on the latest

generation processing machines giving a wide range of finishes and textures.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click

on photographs to see enlarged versions

Some of the significant

machine installations are:

Spinning

• Ring

Spinning

• Total 50,000 Spindles

from LMW.

• Blow Room Lines

are from Trumac while the Cards,

Combers, Drawframes,

Simplex and Ring Frames are from

Lakshmi Machine Works.

• Open

End Spinning

• Total 1440 Rotors of

Open End Machines from Schlafhorst.

• Blow Room Lines

and Carding Machines are from Crosrol.

• Drawframes from

VOUK.

• Post

Spinning

• Autoconers from

Schlfhorst; and

• T.F.O.s from Star

Volkman.

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

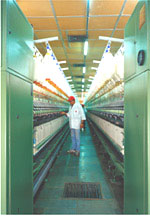

Open

End Spinning

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lakshmi

Reter Ring Frames |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auto

Coners

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weaving

• Preparatory

• Warping Machines,

Sectional Warping and Sizing Machines

are from Benninger, Stormac and Zell.

• Looms

• 214 Sulzer looms

and 598 Shuttle looms.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sulzer Looms

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Processing

• The processing

machines include a Singeing & Desizing

machine from Pyrex.

• Pre-Treatment Range,

Chainless Merceriser and Continuous

Dyeing Range from Benninger/Monforts.

• The Rotary Printing

machine is from Stormac.

• Sueding machine

from Sucker Muller.

|

|

|

|

|

|

|

|

|

|

Pre

Treatment Range

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous

Dyeing Range

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Benninger

Merceriser

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Testing

• The mills have a very

strong infrastructure for testing fabric at all

stages. This includes

Lab dipping machine from Roaches, Lab testing

equipment from James H. Heal and Spectrophotometer from Data

Color.

Modernization

and Expansion Programme

The Textile

division at Phagwara is in the process of further modernizing its facilities

and expansion. This includes the addition of latest generation Cards

and Spindles. The company is also replacing its shuttle looms with latest

Airjet looms. In order to meet the growing demand, another Continuous

Dyeing Range from Benninger/Monforts is also being added.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Research

and Development

Centre

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Boiler

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|